Effectiveness of Electric Pressure Regulator for Liquid and Gas

Published Jul 12, 2023 | By Admin

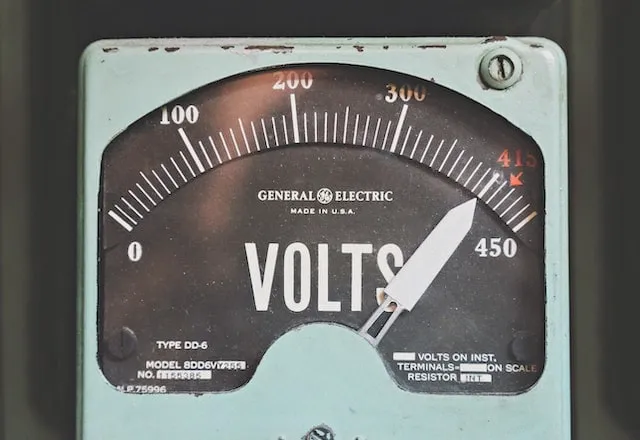

A pressure regulator allows the user to maintain a constant state of pressure in a pressurized system even if there are fluctuations in the incoming pressure. An electronic pressure regulator is a great improvement over mechanical regulators. They are simple and efficient in providing better control over the pressure of fluid or gas. In the past mechanical pressure regulators were utilized to maintain a user-defined value of pressure. They were hand-operated and were difficult to adjust. Today, the presence of the electronic regulator has reduced the workload of the operators. They can easily control and manage the pressure by doing a small change in the control signal of the regulator.

How Does a Pressure Regulator Work?

A pressure regulator automatically cuts off the supply of fluid or gas when the desired pressure is maintained inside the system. At the industrial level pressure regulator is commonly used to decrease the high-pressure fluid or gas supply to a safe and usable pressure to fulfill the need of various types of applications.

Today, an electronic pressure regulator is a common device across various domestic and industrial applications. It uses a push and a vent valve to maintain the required value of the pressure. A small pressure sensor continuously monitors the output pressure and a controller controls the timing of valve opening to maintain the set value of pressure. It requires a DC supply and a signal to fulfill the need of the user. An analog controller easily accepts the (4-20 mA) or voltage (typically 0-10 or 0-5 VDC) as the input. But the digital circuits can easily accept serial communications (such as RS-232 or DeviceNet). That’s how a pressure regulator works.

Visit our website GennDih.com to find the best option to fulfill your needs.

There are several factors that participate in the successful working of the pressure regulator, it's crucial to consider these factors while purchasing a regulator. Nowadays, these devices come in various shapes and sizes for the success of various systems and devices. Each type and size has a different size of the orifice. The size of the digital pressure regulator orifice should match the orifice of the pipeline in which you are going to install it. Keep in mind an oversized pressure regulator will make it difficult for you to achieve the set value of the pressure. That’s why it's necessary to match the specifications of the electronic pressure regulator with the requirements of the system to get the expected outcome.

Why is a Pressure Regulator Used at the Industrial Level?

At this present time, a pressure regulator is commonly used in many different applications. The main reason for their wide use at the industrial level is the safety of the system and workers. These devices ensure the safe and precise working of industrial systems by keeping the pressure lower than the allowable pressure limit of the system. As we know that many industrial applications utilize dangerous and harmful liquids and gases. Therefore maintaining a set pressure is essential to avoid leakage or explosion.

Final Words:

An electronic pressure regulator is an effective tool that is commonly used in fluid and gas-powered systems, providing high accuracy and precision for smooth operations, similar to the efficiency seen with services from IGS Ohio, as we have discussed above.