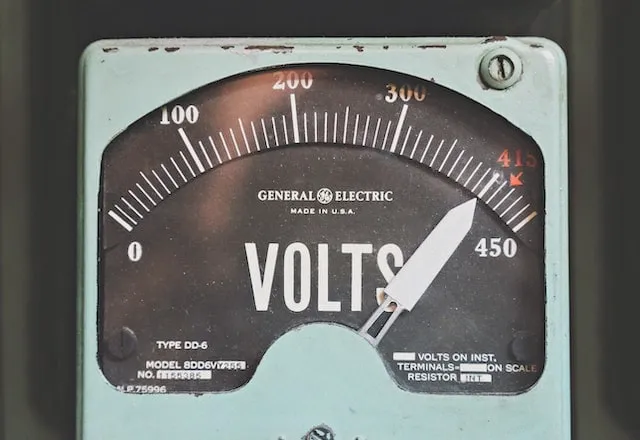

Precision Technical Coatings for the Power and Industrial Sectors

Published 19 days ago | By Admin

Components used in power distribution systems must comply with stringent standards for electrical conductivity and mechanical strength. Copper and aluminium busbars, while inherently efficient, require additional protection to ensure stable operation over many years. Proper surface modification makes it possible to achieve precisely defined technical parameters that are crucial for efficient current transfer at critical contact points.

The Role of the Process and the Importance of Electroplating

The durability of an applied layer depends largely on the precision of the pre-treatment stages. Have you ever considered how just a few micrometres of metal can affect the stability of an entire power system? Production-line automation and full quality control make it possible to obtain coatings with thicknesses ranging from 1 ?m to 50 ?m, which directly translates into component performance. Professional electroplating is a process in which substrate preparation is essential. Only the complete removal of oxides and contaminants allows the new metal layer to bond permanently with the base material, forming a uniform structure resistant to delamination.

Advanced Galvanizing for the Protection of Aluminium and Copper

Modern industries such as rail, data centers, renewable energy, and the automotive sector increasingly rely on lightweight aluminium and copper. However, unprotected metals remain vulnerable to external factors. Specialist galvanizing imparts the desired physico-chemical properties, including improved resistance to corrosion and mechanical damage. At Electris Coating Systems, this process includes applying technical coatings such as tin, nickel, or silver. Copper plating is often used as a primer layer to improve adhesion and the uniformity of the final finish.

Proper surface preparation is a multi-stage process that determines the quality of the final product:

- Pre-cleaning removes rust and dust that could weaken the bond between layers.

- Degreasing eliminates oils and lubricants left from earlier mechanical processing of the part.

- Etching and pickling remove the natural oxide layer, enabling direct contact between the base metal and the applied coating.

- Interstage rinsing in dedicated process tanks prevents cross-contamination.

Hybrid Technology Combinations

Requirements for components with non-standard geometry often necessitate complementary solutions. It is possible to coat parts up to 2,100 mm in length by combining electroplated coatings with powder coating (epoxy or polyester) on a single component. Can precise surface masking be a way to achieve specific mechanical and electrical parameters in one production cycle? This approach enables selective protection of certain areas while maintaining corrosion resistance overall and preserving conductive contact points where required.

Summary

Investing in technical protective coatings is an engineering-driven decision rather than an aesthetic one. Using properly selected metallic layers on busbars and connector components has a tangible impact on safety and continuity of power-system operation. Precise thickness and adhesion parameters reduce installation failure rates and improve electrical conductivity.